Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Description

Product Attributes

Model No.: L022769

Brand: NONE

Material: Aluminum

Deck: Double

Cavity Number: 1

Type: Power System

Weight: 729.6g

Die Casting Machine: Cold Chamber

Supply Ability & Additional Information

Packaging: carton, PE pallet, PE flow box, steel box, wooden pallet, container

Productivity: 5300/MONTH

Transportation: Ocean,Land,Air

Place of Origin: NINGBO

Supply Ability: 60000/MONTH

Certificate: IATF16949:2016,ISO14001:2015,ISO45001:2018

HS Code: 7616991090

Port: NINGBO,SHANGHAI

Payment Type: T/T

Incoterm: FOB,CFR,CIF,FCA

Packaging & Delivery

Product Description

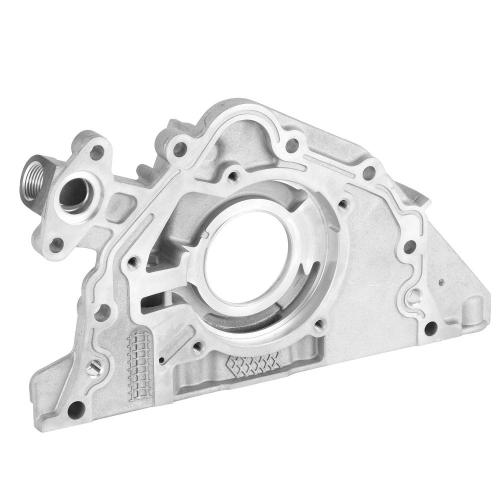

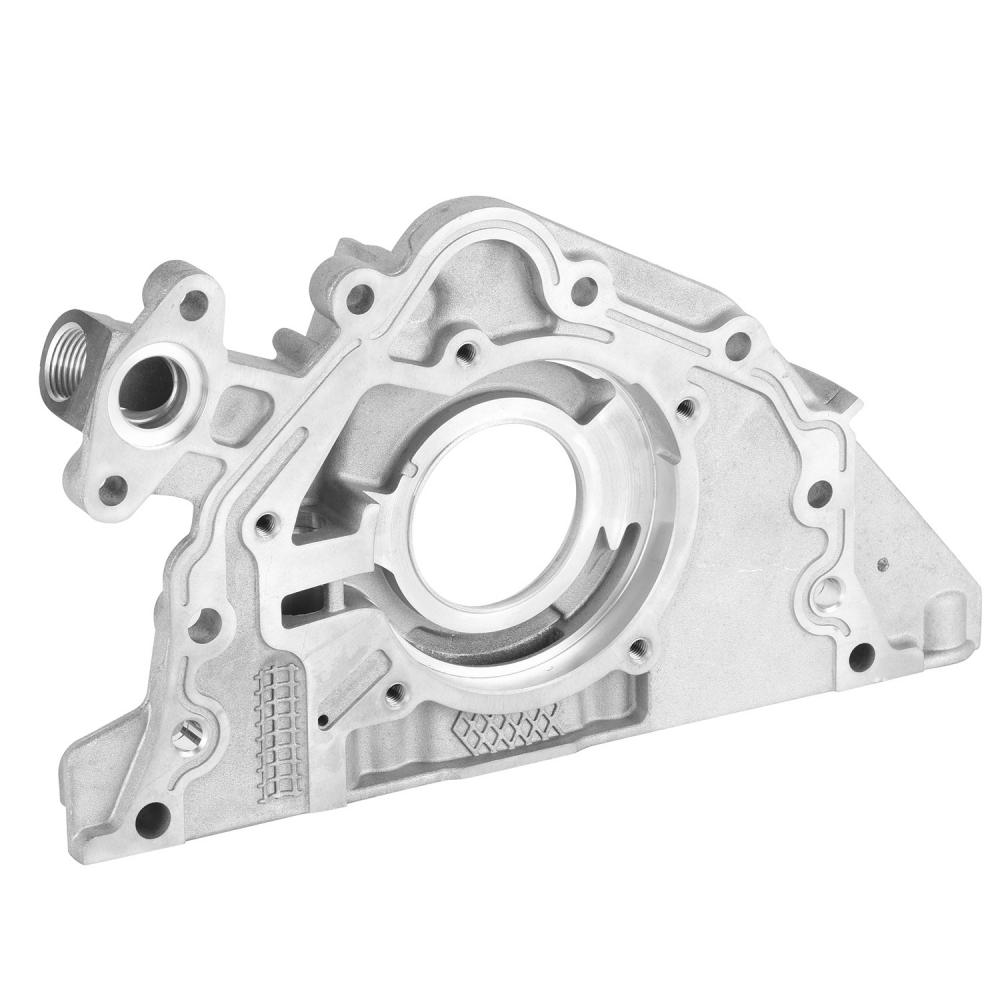

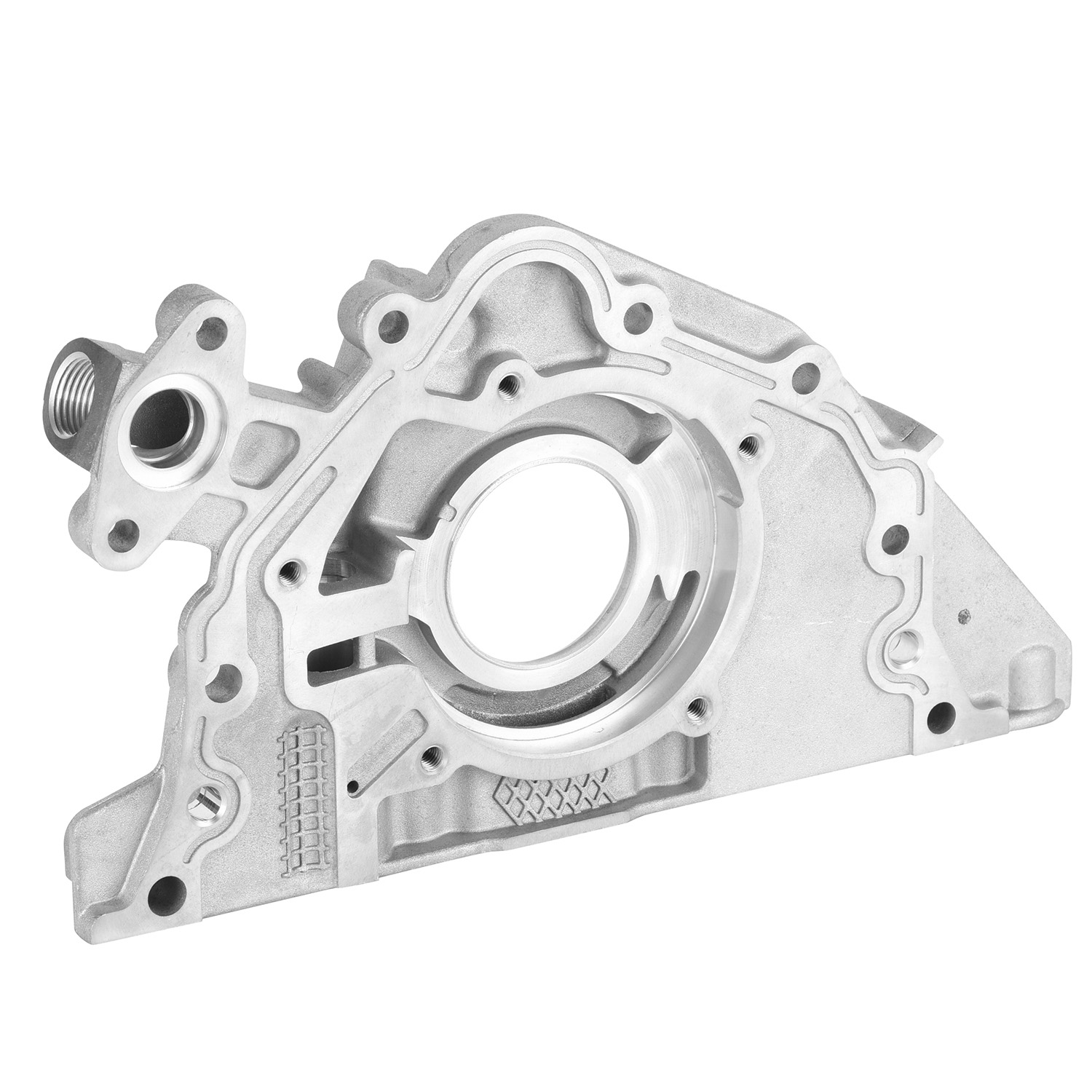

Aluminum Alloy Die Casting side cover ADC12,

The material for this part is ADC12. During the die casting. Higher specific pressure is required, so that higher filling speed can be obtained.which is beneficial for alloy to overcome mold filling resistance.and effectively fill each part of the cavity.

Meanwhile, the speed of die casting is also very important.the ejection speed will affect the quality of Aluminum and steel alloy die casting housing.

The another key point of affecting the quality of Aluminum housing is the pouring temperature.

the temperature can not be too high or too low. both of them will cause the shrinkage.

The thinner the wall thickness is, the more complex the die casting is and the higher the mould temperature is, which is beneficial to the filling of the alloy liquid.

Material: ADC12

Cavity Number: 1

Process Technology: High pressure die casting, Cold Chamber

Product Dimensions: Customized

Casting General Tolerance: Grade GB-CT4

Surface Finish: Polishing

Flow Processes: Die casting, Degating to remove the residual of the gate, Polishing and Deburring to remove the burrs, Polishing to remove the parting line, flash,CNC Milling, Cleaning, Packaging, Storaging, Shipping

Control Measure: Incoming Material Test, First Article inspection, Routing inspection, Final item inspection, and Outgoing quality control

Inspection Equipment: CMM, Caliper, Plug Gage, Screw Gauge

Application: Auto Parts

Certificate: IATF16949:2016,ISO14001:2015,ISO45001:2018

Lead Time: 30-35 days

Trade Term: FOB Ningbo

Hot Products

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.