Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Description

Product Attributes

Model No.: BL101

Brand: NONE

Type: Windscreen Wiper System

Material: Aluminum

Muffler Type: Front Muffler

Deck: Double

Surface Finish: Electrophoresis Coating

Cavity Number: 1

Weight: 250-3000g

Supply Ability & Additional Information

Packaging: carton, PE pallet

Productivity: 3000/MONTH

Transportation: Ocean,Land,Air

Place of Origin: NINGBO

Supply Ability: 50000/MONTH

Certificate: IATF16949:2016,ISO14001:2015,ISO45001:2018

HS Code: 7616991090

Port: NINGBO,SHANGHAI

Payment Type: T/T

Incoterm: FOB,CFR,CIF,FCA

Product Description

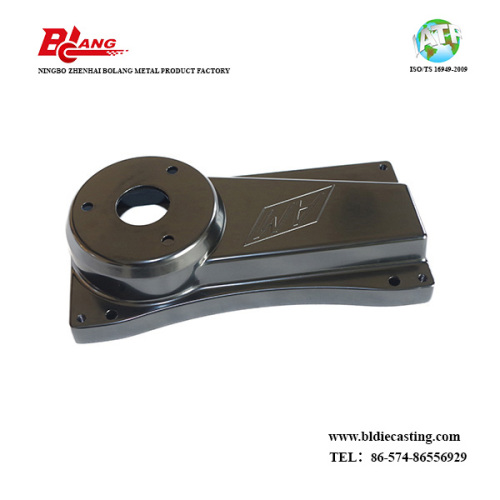

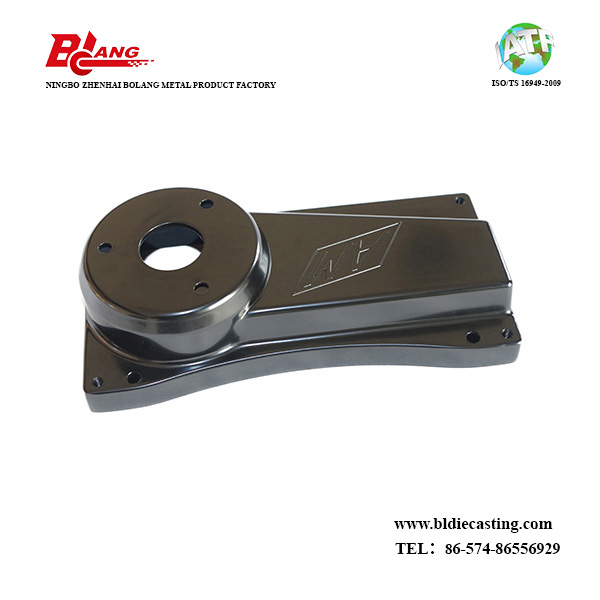

Auto Part of High Accuracy CNC Machining, this part carried Die Casting standard of Grade GB-CT4, the part has small wall thickness, meanwhile, the part have structure of Small cavity, which usually easily cause problem of mold sticking, pull mark etc.

Auto Equipment Parts: Teeth Milling Machine Connector Shell

Die Casting Machine: 280 ton

1 product per die

Material: ADC-12

Product Dimensions: 231.7mm*97.8mm*38.1mm

Casting Precision: Grade GB-CT4

Machining Precision Axle hole: ±0.01mm

Technological Process: Die casting, Degate, Burring,CNC Milling,Polish,Spray Coating,Cleaning, Packing, Delivery

Control Measure: First item inspection, Routing inspection, Final item inspection, Incoming test and Outgoing quality control

Inspection Equipment: CMM and Air Gauge

Surface Treatment: None

Certificate: IATF16949:2016,ISO14001:2015,ISO45001:2018

Lead Time: 30-35 days

Trade Term: FOB Ningbo

The small wall thickness means the part probably happen to deform during production, which will cause actual application issue. What's more, the part surface area is big, but the thickness is small, in this situation, the far end from the location of injection, the melting aluminum will have risk of solid earlier than expected, it will cause short casting at the far end of the part, then while the part is cooled to indoor temperature, the part will have shrinkage porosity inside.

The part has requirement of surface finish of E-Coating, which has process of curing in hot thermal oven, the temperature usually be up to 170-200 degree, the porosity mentioned above will expand and get out from the part, result in pits and bubbles on the coating. So in the inspection work instruction, there is request that the QC inspector should fracture the part with hammer, then check the section particle with magnifying lens to see if there is problem of porosity on the section. The inspector also will make a record of the part weight, and control through weighing the part. All these action is to avoid batches rejected while e-coating.

Hot Products

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.